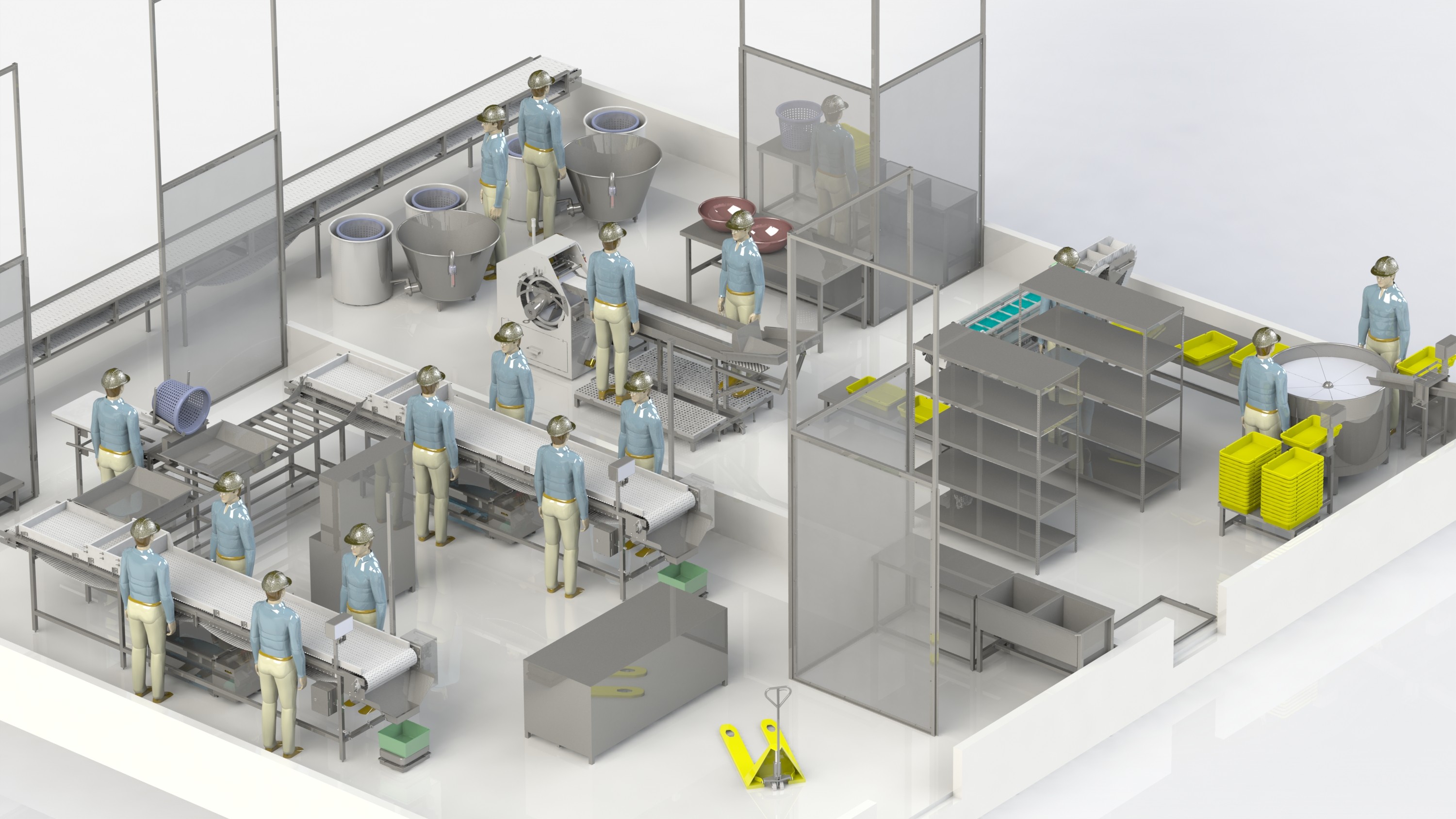

цеха

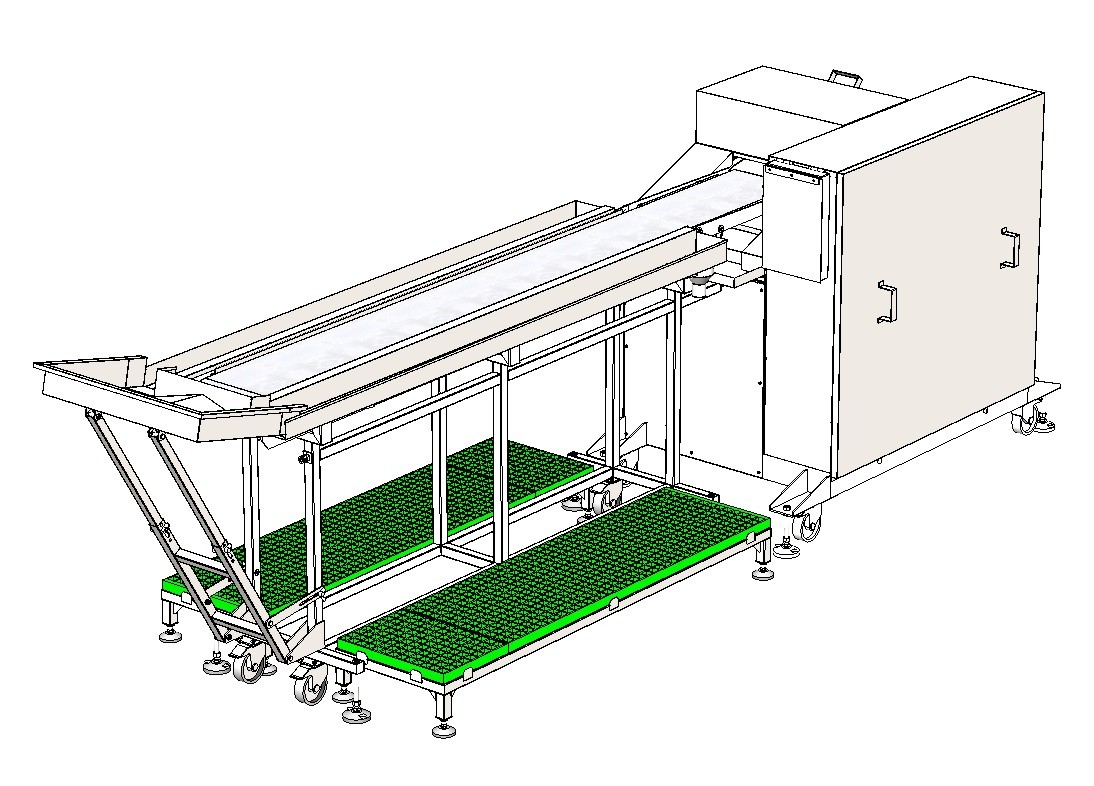

Fixing the anchor is now performed not in the bath, but on the conveyor. The continuity of the process provides more high productivity with fewer staff. Brine salinity and temperature are now controlled automatically. The residence time of the yastyk in the solution is regulated by the speed of the tape, and the fixing time itself is determined by the caviar master.

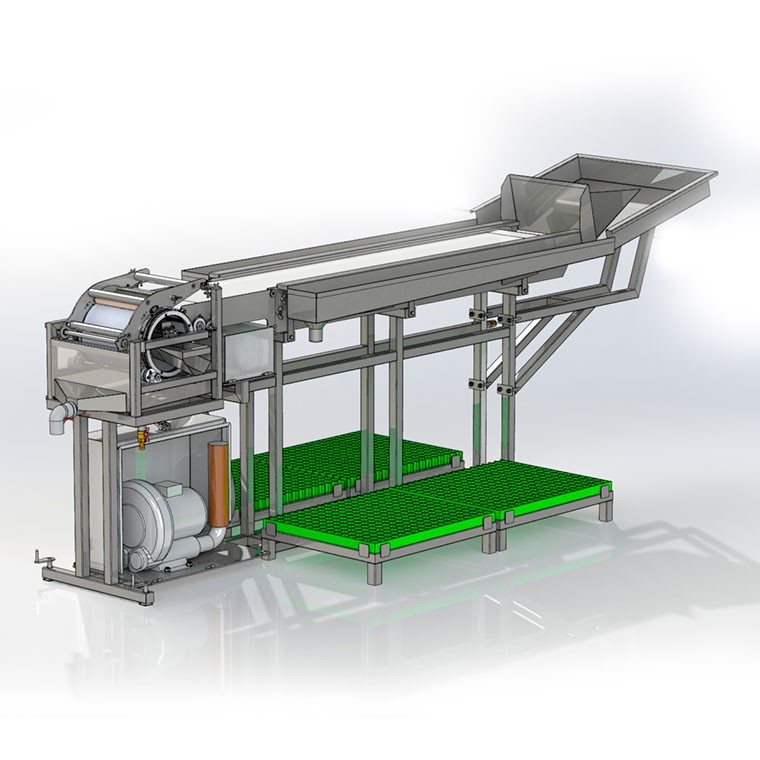

Caviar punching is performed by the IS500 caviar separator, capable of passing through up to 500 kg of caviar per hour with a yield of up to 85% “good” on fresh ripe caviar. Smaller dimensions compared to separators of previous models or compared with similar machines of competitors, allow you to save production space and thereby save on the cost of construction. The machine is easy to maintain and operate.

The seemingly old and familiar caviar centrifuge underwent internal design changes, which made it possible to increase the service life of individual machine elements, increase smooth operation and reduce vibration. The changes also had a beneficial effect on the cost of the product.

Inspection transporters can be equipped with vacuum tweezers, which will allow girls not to waste time on removing a hand with a substandard particle and 2-3 times increase the productivity of each person engaged in the inspection.

Equipment composition:

- Reception and sorting table

- Weight posts

- Buffer rack.

- Table

- Anchorage conveyor

- Buffer table

- Caviar separator IS500

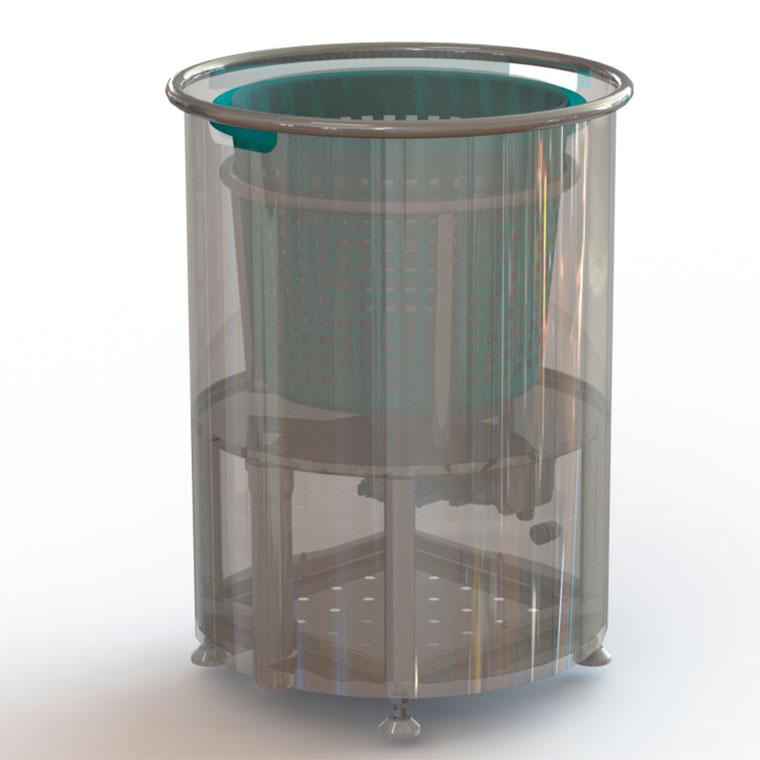

- Salting capacity 250L

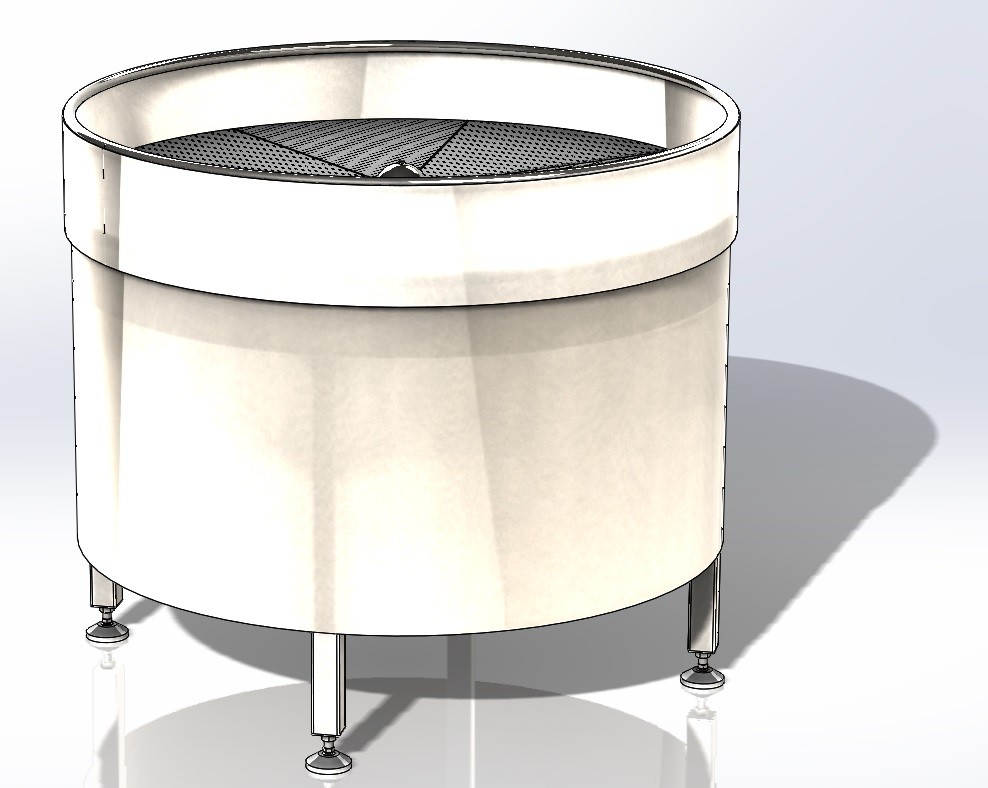

- Caviar centrifuge

- Conveyor 11m

- Weighing table

- Antiseptic application post

- Inspection transporters

- Vacuum tweezers

- Antiseptic storage and weighing cabinet

- Table-cabinet for storage and weighing of antiseptic

- Two-section sink

- Table

цеха

Fixing the anchor is now performed not in the bath, but on the conveyor. The continuity of the process provides more high productivity with fewer staff. Brine salinity and temperature are now controlled automatically. The residence time of the yastyk in the solution is regulated by the speed of the tape, and the fixing time itself is determined by the caviar master.

Caviar punching is performed by the IS500 caviar separator, capable of passing through up to 500 kg of caviar per hour with a yield of up to 85% “good” on fresh ripe caviar. Smaller dimensions compared to separators of previous models or compared with similar machines of competitors, allow you to save production space and thereby save on the cost of construction. The machine is easy to maintain and operate.

The seemingly old and familiar caviar centrifuge underwent internal design changes, which made it possible to increase the service life of individual machine elements, increase smooth operation and reduce vibration. The changes also had a beneficial effect on the cost of the product.

Inspection transporters can be equipped with vacuum tweezers, which will allow girls not to waste time on removing a hand with a substandard particle and 2-3 times increase the productivity of each person engaged in the inspection.

Equipment composition:

- Reception and sorting table

- Weight posts

- Buffer rack.

- Table

- Anchorage conveyor

- Buffer table

- Caviar separator IS500

- Salting capacity 250L

- Caviar centrifuge

- Conveyor 11m

- Weighing table

- Antiseptic application post

- Inspection transporters

- Vacuum tweezers

- Antiseptic storage and weighing cabinet

- Table-cabinet for storage and weighing of antiseptic

- Two-section sink

- Table